NAPIER GRASS TO BIO-CNG PLANT, UP

Salient Features

The present project is an integrated NAPIER TO BIO-CNG project as a commercial activity which has following salient features-

1. Total project cost Rs. 8 Cr.

2. 2.4 MT Bio-CNG per day (800 MT per yr) with gas purification and bottling plant, based on anaerobic digestion of NAPIER GRASS available from member farmers nearby plant and any other suitable agricultural wastes, cow dung etc which may be available. Bio-CNG will be sold to CNG outlets for vehicles/ other applications. Manure disposal sales 2000MT to farmers.

3. Procurement of 15,000 MT of Napier Grass to be made from member farmers under buy-back agreement.

4. Direct/ indirect employment generation of around 1000 persons.

5. Income generation for farmers almost triple to Rs.2.0 Lacs per acre per year.

6. Share holding / profit distribution to all member farmers as per their shareholding.

7. 5,000 MT/ year energy Coal replacement.

8. Coal ash contains harmful ingredients so it has to be dumped safely, whereas Napier grass can be used as fertiliser also and can be spread in fields as well.

9. 15,000 MT CO2 reduction per year by way of equivalent Coal replacement.

10. Dry Napier grass has almost 70% calorific value of coal hence a good replacement as energy crop.

11. Latest technology of channel based digester shall be used to start project in minimum time with minimum cost.

12. The project shall use all types of agricultural refuse/ waste, like rice/ wheat straw etc. so all the environmental problems shall be avoided.

13. It is a farmers cooperative movement experiment and shall be replicated in all the parts of country very soon.

14. Gobar from Gaushalas can also be used in the process and shall create additional income to run Gaushalas/ milk dairies.

15. The project shall start with 500 farmers and shall be increased to 5000 farmers in every district.

16. Full project operation time period is 6 months from the start of project activities.

Steps of Integrated Project

The integrated project shall be set up in following steps-

1. Buy-back agreement with farmers to grow Napier grass in one Acre land each and supply back to the company as per agreement terms.

2. Establishment of Bio-CNG plant and supply of CNG to dispensers.

3. Sale of organic manure back to farmers.

General Bio-gas Plant Operation Procedure

The Bio-CNG plant shall use Napier grass available from nearby farmers as a crop. The Napier grass is mainly animal feed crop but has a high energy yield with less of efforts. The biogas is generated as a result of anaerobic digestion of crushed Napier grass slurry in a closed, dark and oxygen deficient space. The biogas generated consists of 60% Methane, 40% Carbon di oxide and traces of Hydrogen sulphide. The biogas is purified in a scrubber and pure methane is stored in a balloon. This pure methane, also called bio-CNG is compressed through a compressor at 250 Kg/cm2 pressure to fill in the cylinders in a cascade, which is transported to a CNG filling station nearby for filling into the transport vehicles.

For initial digestive activity to start Napier slurry shall be mixed with culture of bacteria. The biogas generation is best achieved at 35 deg C temperature, hence a heating system is also employed to keep the digestate liquid at optimum temperature. For heating system an innovative hot water circulation system shall be employed in the new design of digester and waste heat recovery exchanger and biowaste boiler shall be utilized.

Detailed Project Description

1. Feedstock

This plant can use 40 tons of Napier grass crushed to 5% solid composition. The plant can also use pressmud and some 10% cow dung, chicken litter, green leaves waste or both waste materials in a combination. The feedstock is low cost and consists of Napier grass, pressmud, cow dung, food waste, poultry waste, MSW and other bio- degradable stuff from nearby villages/ plants.

The amount of raw material may change according to the availability and biogas generation capacity. Other bio-degradable waste stuff shall be collected through pharma tractors and also using special vehicles designed for transporting the wastes from nearby villages in enclosed containers to prevent air pollution by the SPV which can also pay the restaurants etc. (say) INR 200/MT for the waste collected.

The Napier grass shall be purchased from farmer members who will enter into buyback agreement with the company in a 10 km area of BioCNG plant. We are going to register around 500 farmers to grow Napier grass for our plant and supply to us for an agreed rate of purchase. The member farmers shall also be given a shareholding in the company on the model of cooperative sugar mills.

2. Market for the products

There are mainly two products of the plant, the Bio-CNG and Organic Manure.

BIO-CNG is to be supplied to consumers directly as a replacement for CNG as a fuel in industrial utilization, or as a cooking fuel in the restaurants at the nearby markets. It can also be used as an automobile fuel using gas dispensers and as high-grade industrial fuel for cutting and welding applications.

Organic Manure, the solid and liquid bio-fertilizers are in demand as a premium replacement for chemical fertilizers and are to be directly marketed using appropriate channels to the member farmers and farming communities/ companies.

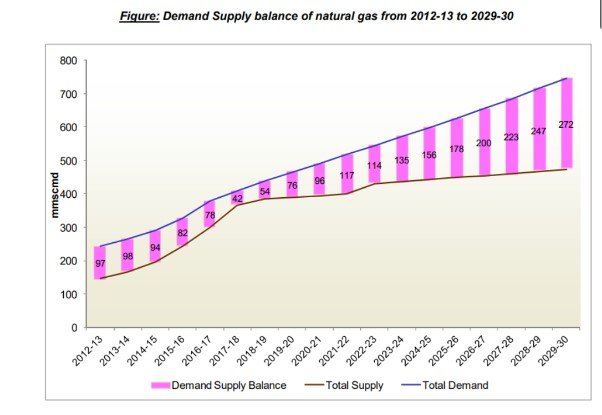

Following figure indicates the future demand survey for CNG, natural gas, as a fuel in India.

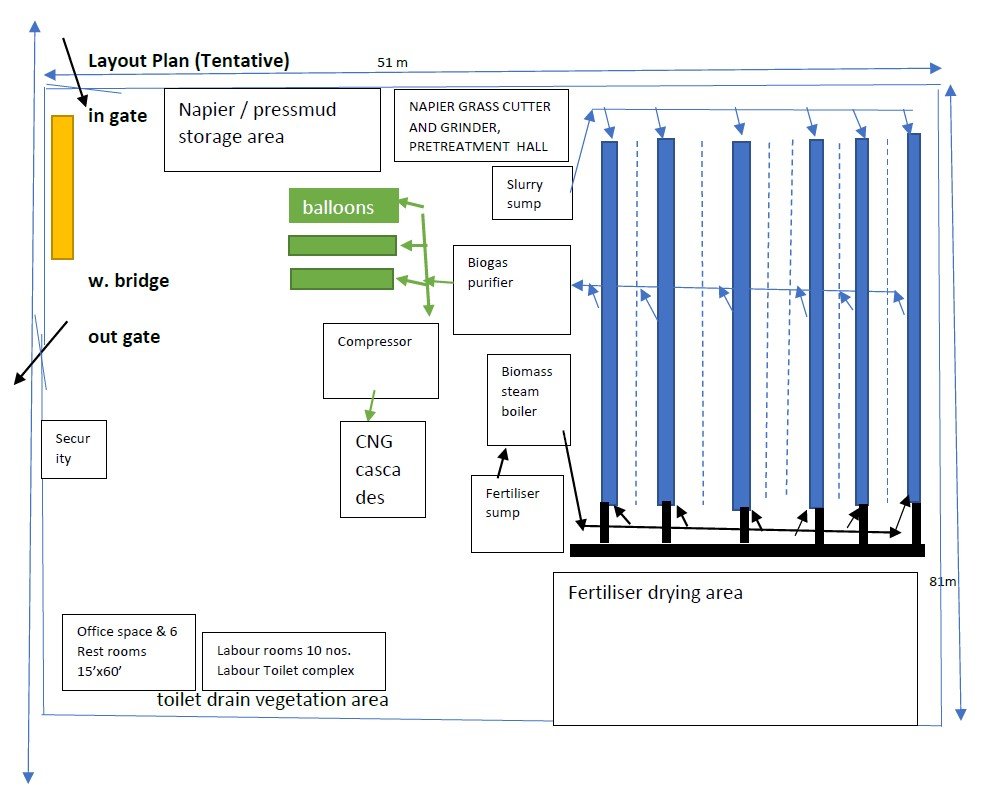

- MAJOR EQUIPMENT

- 1. Civil works for Digester of channel type with required capacity.

- 2. Associated liquid & Gas piping system for conveying substrates and Liquids

- 3. Slurry Tanks with Mixing Agitator & liquid out tank

- 4. Feeding pump (Screw Pump), liquid handling pumps

- 5. Biogas purification system & Booster Compressor with auxiliaries

- 6. Biogas balloon for storage and shed construction

- 7. Bio-CNG 250 bar compressor & Cylinder cascades for one day filling capacity

Napiar cultivation.avilable 2.5 acore aria.suply napiar grass.

Thank you for sharing. Could you please explain in detail about the Napier cultivation on 2.5 acres,This will help us understand better

Interested.suply store.napiar plant available.

Please feel free to connect at sbincorporeal@gmail.com with proper details